Overview

Train journeys should be fast, smooth, and reliable—but keeping trains running efficiently is a constant challenge for rail operators. A major weak spot lies in the connection between trains and the overhead power lines they rely on.

To address this, researchers at City St George’s, University of London are leading an innovative project that has developed sensor technology that helps keep trains on track, engineers safer, and passengers moving

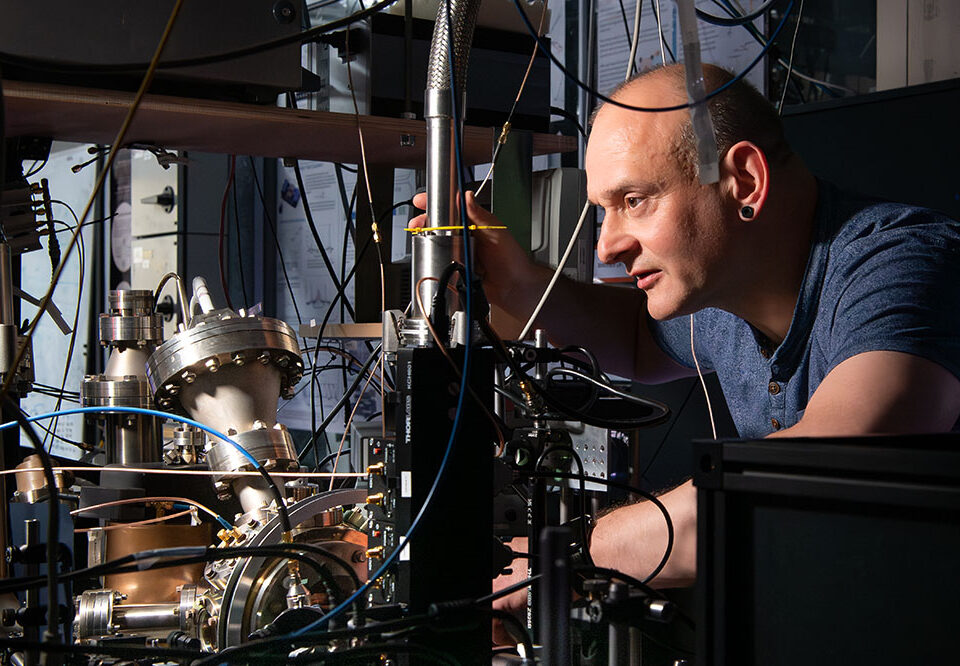

Professors Tong Sun OBE FREng and Kenneth Grattan OBE FREng have developed a smart pantograph — a device that collects electricity from overhead lines and uses built-in sensors to spot problems before they cause delays, breakdowns, or costly repairs. It is a development that could transform the way rail networks maintain and monitor their electrification systems.

The Challenge the Research is Responding To

The pantograph is the key part of an electric train that connects to overhead power lines. If it doesn’t make proper contact with the wires—or becomes damaged—it can lead to serious disruption: train delays, cancellations, and expensive on-the-spot repairs.

Worse still, engineers often have to fix these problems trackside, sometimes in unsafe or hard-to-reach areas, and without knowing exactly where the issue lies. This makes maintenance reactive, risky, and expensive.

Rail operators have long needed a solution that can spot faults before they happen, keep trains running smoothly; improve safety for engineers, avoid unnecessary environmental and financial waste.

Partnerships Involved

This project has been developed in collaboration with Faiveley Brecknell Willis, a UK-based world leader in railway electrification technology and Network Rail, the UK’s rail infrastructure owner and operator. These partnerships have enabled the research team to test, refine, and roll out their technology in real-world rail operations.

Our Research

Working with Faiveley Brecknell Willis, Professors Sun and Grattan developed a self-sensing pantograph—a smart version of the traditional device that can be fitted onto existing electric trains without major changes.

Here’s how it works:

• The pantograph looks and functions like a normal one but has fibre optic sensors inside.

• These sensors are extremely durable and can detect force, position, temperature, and vibration, using light signals instead of electricity—making them safer and more accurate in harsh rail environments.

• The system also integrates with GPS and onboard cameras, allowing engineers to track the exact location of potential faults and take action in advance.

Since 2018, Network Rail has installed smart pantographs on its high-output maintenance trains, with data from these systems also helping to manage the Great Western mainline. This means engineers can now see what’s going wrong before it breaks, plan repairs during scheduled downtime, and avoid costly and dangerous on-the-fly fixes.

Our impact

The smart pantograph offers multiple benefits—for passengers, engineers, rail operators, and the environment:

• Better journeys for passengers: With fewer breakdowns and delays, people enjoy smoother, more reliable travel. That makes rail a more attractive choice, encouraging greener transport habits.

• Lower maintenance costs: Rail companies can save millions by switching from emergency repairs to predictive maintenance, fixing issues before they cause problems.

• Improved engineer safety: By knowing exactly where a fault is likely to occur—and what conditions caused it—engineers can plan safer, more informed interventions.

• Environmental sustainability: Because the pantograph fits onto existing trains, there’s no need to build new equipment or scrap the old—saving materials and reducing waste. Plus, smoother operation extends the life of trains and overhead lines.

As Professor Grattan puts it:

“Passengers want a smooth and fast rail journey. They can’t have that if trains break down. With smart pantographs, we can keep trains running for longer and help prevent disruption.”

This research shows how smart engineering and sensor technology can make modern railways more resilient, efficient, and sustainable – helping the UK rail network meet the growing demand for clean, reliable transport.